-

VMC 1160 CNBC Machining Center Now the Upgraded Version,with THK screw guide rails, Proton Lubricating Oil Pump

$77,999The BTMC V-1060 CNC Vertical Machining Center is a high-precision, multifunctional solution for heavy-duty general machinery processing. With a table size of 1200x600mm and travel ranges of 1100x600x600mm (X/Y/Z), it supports a maximum table load of 800kg. Equipped with a BT40 spindle, 24-tool magazine, and speeds ranging from 20-8000 RPM, it ensures efficient and accurate operations. The machine features advanced CNC control options (Fanuc, Siemens, Syntec, GSK) and offers ±0.005mm positioning accuracy with ±0.001mm repeatability. Designed for reliability and versatility, it comes with a 1-year warranty and is ideal for demanding industrial applications.

-

VMC 855 Milling Machine Machining Center CNC Milling Machine Vertical Machining Center VMC855

$79,500The VMC 855 Milling Machine Machining Center offers exceptional precision with 0.0075mm positioning accuracy and 5-axis capability for complex operations. Ideal for industries like manufacturing and energy, it features customizable options, durable components with a 1-year warranty, and comprehensive overseas after-sales support, ensuring reliable and adaptable performance.

-

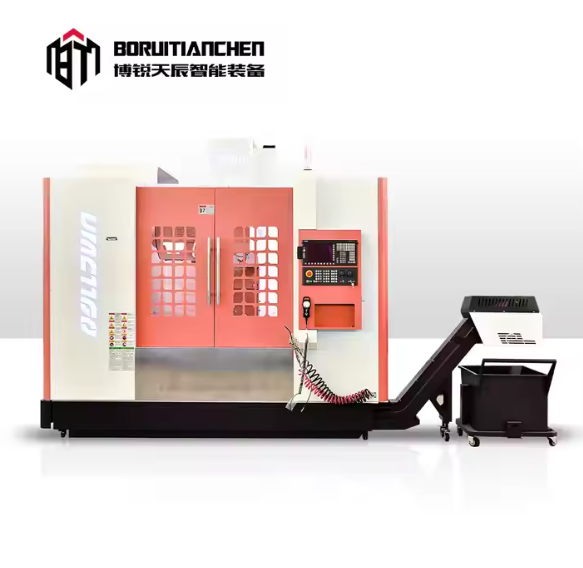

VMC1160 Premium Vertical Machining Centre New Condition Fanuc Gsk Mitsubishi Siemens CNC Control Competitive Price BT40 KND

$71,999The Borui VMC1160 Vertical CNC Machining Center is a high-performance solution for complex metalworking tasks such as milling, drilling, tapping, and turning. Featuring a 1200x600mm table with travel ranges of 1100x600x600mm (X/Y/Z), it supports up to 800kg table load and operates with 3, 4, or 5 axes for versatile applications. With a BT40 spindle taper, speeds up to 8000 RPM, and a powerful spindle motor (11/15kW), it ensures precision with ±0.005mm positioning accuracy and ±0.001mm repeatability. Equipped with 16 or 24-tool magazines and fast tool changes (1 second), it offers efficient operation. Backed by a 1-year warranty, competitive pricing, and advanced CNC systems (GSK, FANUC, Siemens), it is ideal for steel and metal part processing.